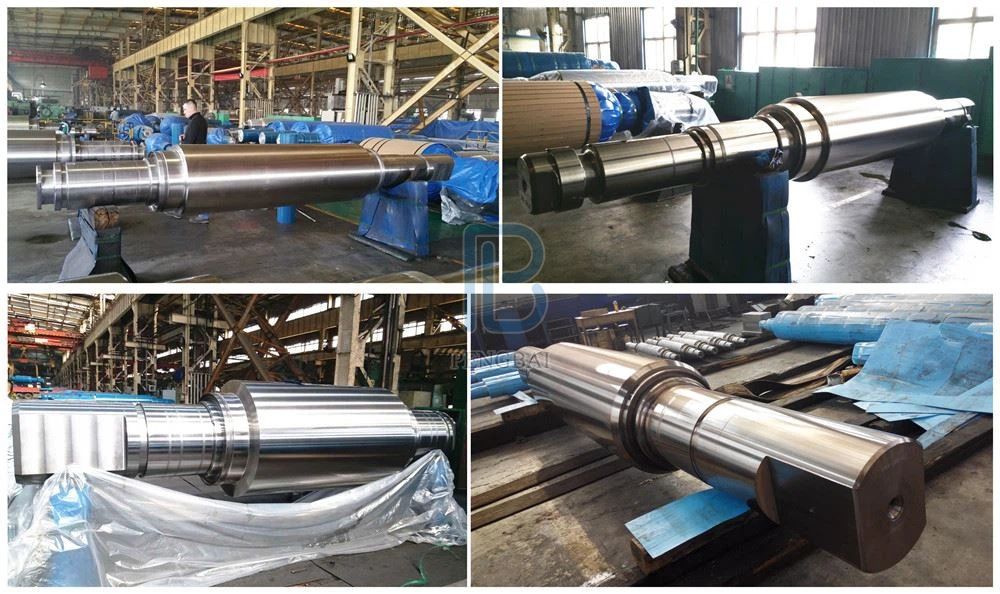

The whole process form melting, casting, forging, heat treatment to final machining and packing is under control of quality system.

Description

1.As a core part of a rolling mill, work rolls are direct contact with rolling material, so its performance is very importance.

2.In order to make the material rolling to be the desired products, must use high quality work rolls.

3.QINPENG can provide high quality work rolls, which has uniform surface hardness as well as in depth.

|

Specification |

Material |

Diameter (mm) |

Length (mm) |

Weight (Tons) |

|

Work Rolls |

9Cr2Mo,9Cr3Mo,MC3, MC5 etc. |

Max. Ø610mm |

Max. 6000mm |

Max. 8.0T |

Equipment Feature

Our company has a complete process chain of material smelting-forging-heat treatment-machining, so that the quality of products can be controlled from the source. The EBT+LF/VD+ESR smelting process can be used in accordance with the standards of the Ministry of Machinery Industry (JB/T) or the technical agreement signed by the two parties, and forged by hydraulic fast forging machines and precision forging machines. And according to user requirements in accordance with the machining state or quenched and tempered heat treatment state delivery.

Working Equipment

1.The company has built a roll production line covering the entire process flow of smelting, casting, heat treatment, and mechanical processing, and is equipped with technologically advanced production equipment in each process link.

2.It has complete inspection and testing equipment, a complete quality assurance system, and excellent product quality control capabilities.

After-sales Mechanism

1.Our after-sales service organization is located in the marketing center, equipped with specialized after-sales service management personnel, responsible for organizing and coordinating customer feedback on quality objections.

2.The company has formulated corresponding regulations, and has made clear regulations throughout the entire process of receiving, transmitting, and processing customer information.

3.For customer feedback on quality objections, we will communicate with customers within 2 working days.