Alloy ductile iron roll is characterized by the ball-shaped graphite in the matrix, through adjusting the compositions of Ni, Cr, Mo adopting different heat treatment technology, pearlitic ductile iron and acicular constitution and different performance of anti-heat impact and resistance to wear.

Description

Alloy ductile iron roll is characterized by the ball-shaped graphite in the matrix, through adjusting the compositions of Ni, Cr, Mo adopting different heat treatment technology, pearlitic ductile iron and acicular constitution and different performance of anti-heat impact and resistance to wear.

Chemical Composition

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Mg |

||

|

Centrifugal |

Static |

SGP I |

2.90-3.60 |

1.40-2.20 |

0.40-1.00 |

≤0.15 |

≤0.030 |

0.10-0.60 |

1.50-2.00 |

0.20-0.80 |

≥0.04 |

|

SGP II |

2.90-3.60 |

1.40-2.20 |

0.40-1.00 |

≤0.15 |

≤0.030 |

0.20-1.00 |

2.01-2.50 |

0.20-0.80 |

≥0.04 |

||

|

SGP III |

2.90-3.60 |

1.40-2.20 |

0.40-1.00 |

≤0.15 |

≤0.030 |

0.20-1.20 |

2.51-3.00 |

0.20-0.80 |

≥0.04 |

||

|

CORE |

2.90-3.70 |

1.40-2.60 |

0.50-1.00 |

≤0.15 |

≤0.030 |

≤0.08 |

≤0.15 |

≤0.50 |

≥0.04 |

||

Mechanical Properties

|

Tensile Strength (kg/mm²) |

450-600 |

|

Bending Strength (kg/mm²) |

800-1000 |

|

Elongation (%) |

0.2-0.5 |

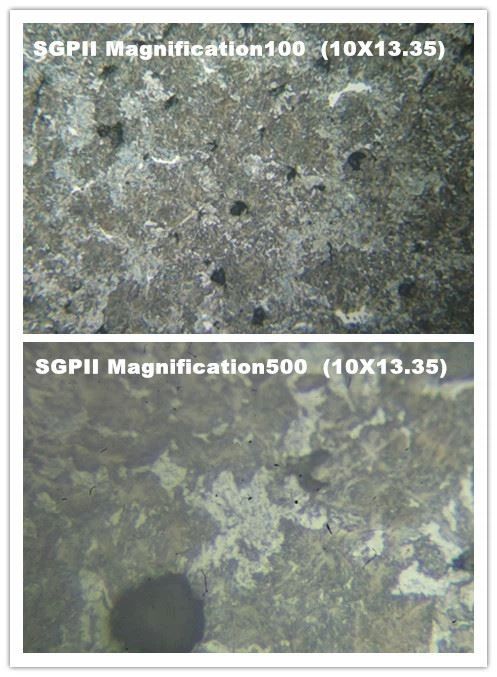

Metallography Organism

Company Information

With more than20 years' history, we are a large and professional enterprise in China that integrates research, development and manufacture of alloy roll into one. The company owns advanced middle frequency furnace, compound centrifugal casting machine, precise and complete metal cutting equipment and advanced and modern quality measurement and control means. The alloy rolls we manufactured have the characteristic of high rigidity, high intensity, good wear resistance, anti crack and anti strip, sell well within the country, have been exported to a couple of countries covering Asia, Africa and Europe, and win good reputations from our customers.

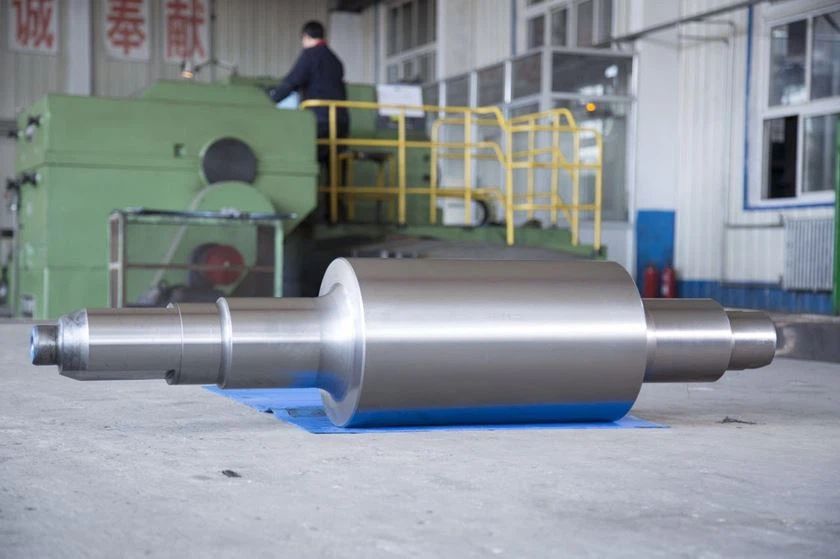

Work shop

We have 3 foundry workshop, 3 processing plants, 2 heat treatment workshop, with 10-30more than 20 tons crane. There are various intermediate frequency furnace foundry 9 sets, 5 sets of centrifugal casting production line.Processing plant are turning, milling, grinding, drilling dozens of various type of lathe, fully equipped. The company also has advanced modern testing equipment, such as: photoelectric direct reading spectrometer, carbon and sulfur analyzer, digital high-resolution desk top optical microscope, ultrasonic flaw detector and so on, for the production of high-quality products and provide support and protection.

Package & Shipping