We manufacture and supply a wide range of international quality work rolls. These work rolls are manufactured with high-quality alloyed steels.

Description

1.These intermediate rolls are manufactured with high-quality alloyed steels. The size and diameter of these work rolls differ as per the client's requirement.

2.The productivity of intermediate roll has increased greatly. The cold-rolled products have high-precision, high-quality and multi model. Intermediate roll is very important.

3.The basic requirement includes:

a.High and even hardness in rllbody,

b. Deep hardness layer,

c.High abrasion resistance;

d. Better spalling resistance;

e. Excellent mechanic property.

Application

Intermediate rolls can be used on cold rolling mill. Designed to provide robust support for work rolls, back-up rolls prevent work roll deflections. It's a key function that helps ensure proper performance of the entire rolling mill.

It is very flexible and can be easily installed. It is of good quality. It is easy to operate, and it could easily fit in.

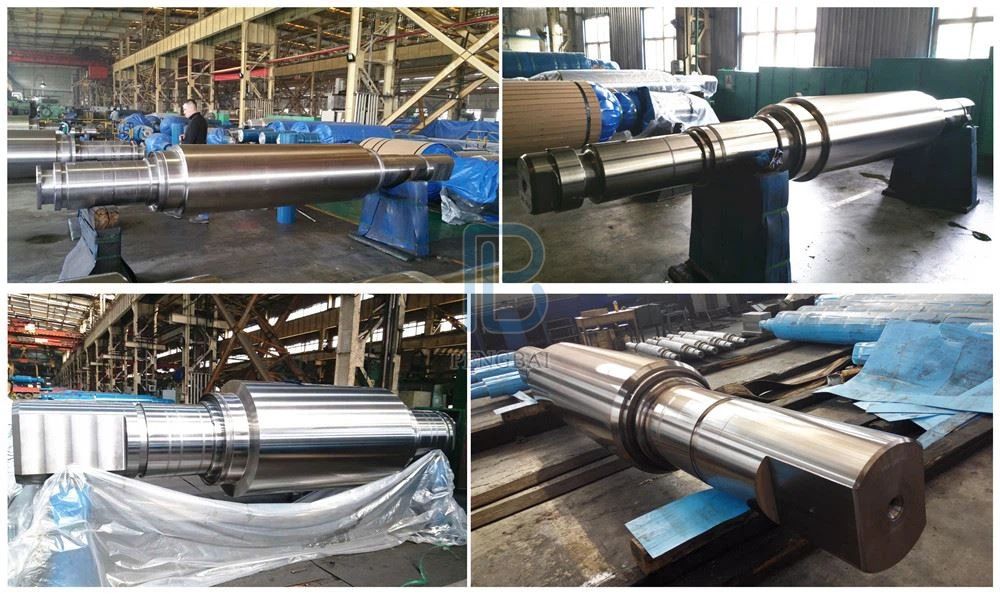

Work shop

1.40T electrical arc furnace, 50T ladle refining furnace, 20T electro-slag remelting furnace, 40T vacuum degassing furnace ensure high quality ingots.

2.1600 to 2500 tons hydraulic press machine, 10 tons electro-hydraulic hammer and 12 meters annealing furnace ensure high quality forgings.

3.Three sets 10 meters pit type quenching and tempering furnace, l set 20 meters horizontal intermediate frequency induction furnace, 2 sets vertical type CNC intermediate frequency/ power frequency/ double intermediate frequency quenching machine ensure mechanical properties/surface hardness/hardness depth to supply high quality products.

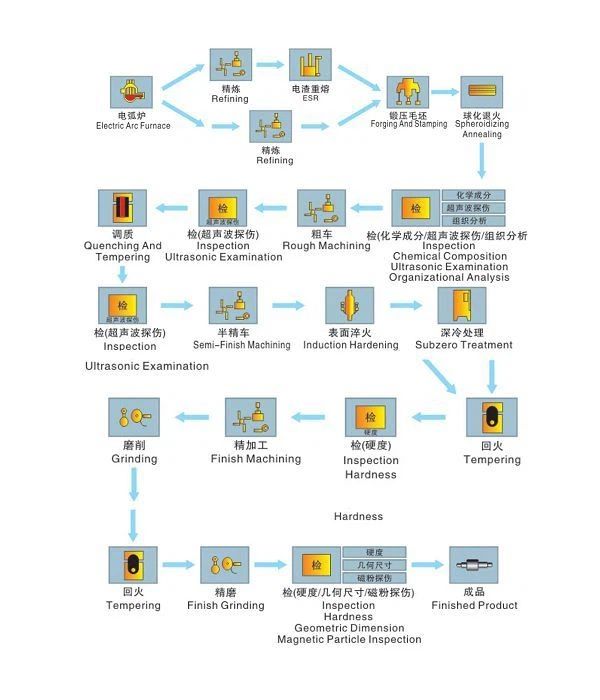

Production process

About US

Our company can produce various kinds of forged mill rolls. In order to meet the customers’ requirements, the rollers can be produced in the way of steel-making by basic electric arc furnace, LF+EAF+VOD, ESR, forging, machining, and heat treatment. Our rolls are wildly applicable for domestic Ferrous, non-ferrous industry, meanwhile export to USA, Japan, Korea, Italy, Spain, Germany, India etc.