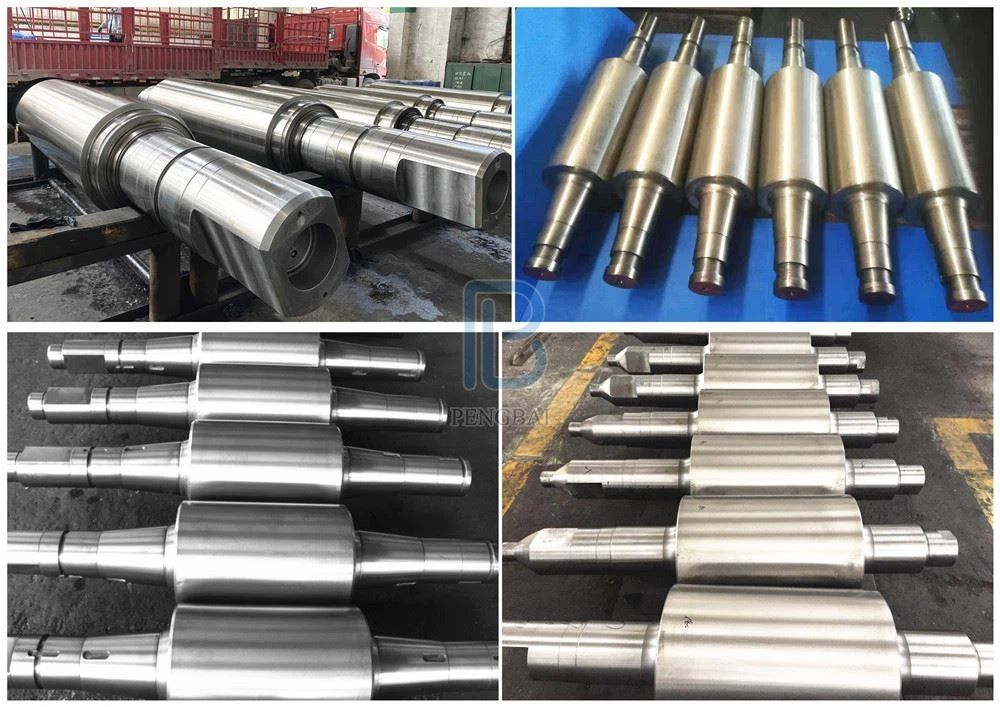

High speed steel rolls, produced by horizontal centrifugal casting process, are all compound rolls with high speed steel as the work layer and nodular iron as the core.

Product Feature

The high speed steel rolls are produced by the horizontal centrifugal casting process, all of which are made of high-speed steel as the working layer. It is a composite roll with ductile iron as the core. This roll material contains a large amount of Mo, V, W, Cr and other alloying elements. High-hardening eutectic carbides and secondary carbides, such as MC, M2C, M6C, are uniformly distributed in the tempered martensitic matrix, making it excellent in wear resistance and hot crack resistance, and it has good surface roughening resistance.

Application

High speed steel rolls are mainly used as the work rolls in the hot strip mills and the finishing stands of bar mills, rings of the universal section mills and finishing stands of the high speed bar mills.

S-HSS rolls are mainly used as the work rolls in the rough stands of the hot sip mills, work and intermediate rolls in the cold strip mills.

A thin adherent oxide film can be formed into the surface for good quality and good abrasion resistance in condition of hot rolling.

Chemical Composition

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

V |

W |

Nb |

|

|

Centrifugal |

HSS |

1.50-2.20 |

0.30-1.00 |

0.40-1.20 |

≤0.03 |

≤0.25 |

3.00-8.00 |

0.00-1.50 |

2.00-8.00 |

2.00-9.00 |

0.00-8.00 |

1.00-3.00 |

|

CORE |

2.90-3.70 |

1.20-2.60 |

0.50-1.00 |

≤0.15 |

≤0.03 |

≤0.08 |

≤0.15 |

≤0.50 |

Mechanical Properties

|

Tensile Strength (kg/mm²) |

500-800 |

|

Bending Strength (kg/mm²) |

650-1000 |

|

Elongation (%) |

0.2-0.6 |

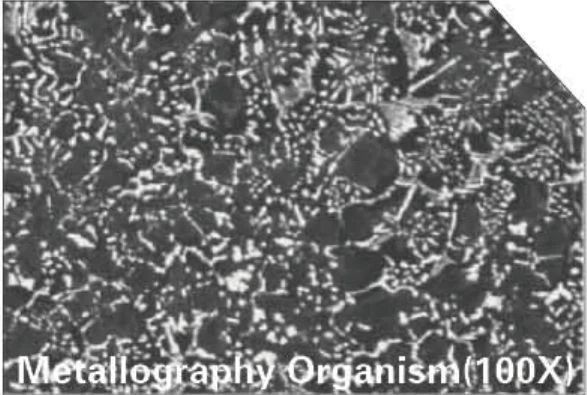

Metallography Organism

Package & Shipping

Our Service

1)We guarantee that all the products supplied are completely new with high quality and technical advanced. What we supplied are conform to the technical performance required by the customers.

2)We guarantee that the guarantee period of the goods supplied is 12 months after the date of signing the certificate of goods acceptance.

3)We guarantees that the goods supplied meet the requirements for the quality and technical performance specified during the guarantee period, if it is due to the responsibility of Qinpeng that the goods supplied do not confirm to the requirements for the specified quality and technical performance, the buyer has the right to lodge the claim.

4)We guarantees that the technical documentation supplied is correct, complete and clear and conforms to the requirements for the design, inspection, installation, adjustment and maintenance of the goods.